Requirements for Parallel Production / Parallel Ownership on the producer side

Traceability and Identification

Producers are required to have an internal traceability and identification system in place to trace back all products to the production process they originate from.

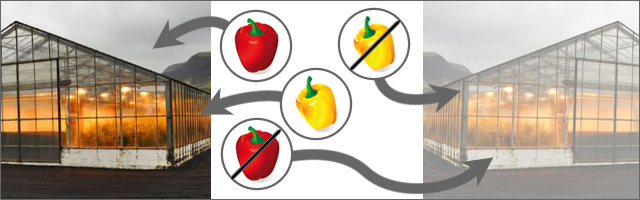

Where possible, visual differences can be used for identification.

Example (click to expand / reduce)

Quiz (click to expand / reduce)

Question 2-2-1

During a GLOBALG.A.P. inspection, the inspector asks the producer how he manages the traceability and segregation of his certified and non-certified grapes. The producer answers that all certified grapes are brought after harvest to the packhouse where they are packed on the first packing line. After packing, they are then stored in the big cold room. The non-certified grapes are packed on the second packing line and stored in the small cold room. Neither the packing lines nor the cold rooms carry identification signs. Is this producer complying with the GLOBALG.A.P. IFA Version 4 Standard?

Correct. Traceability and segregation are fully managed. The packing lines and cold rooms don’t need to be identified using signs as long as the handling procedure is clearly communicated.

Incorrect. Traceability and segregation are fully managed. The packing lines and cold rooms don’t need to be identified using signs as long as the handling procedure is clearly communicated.